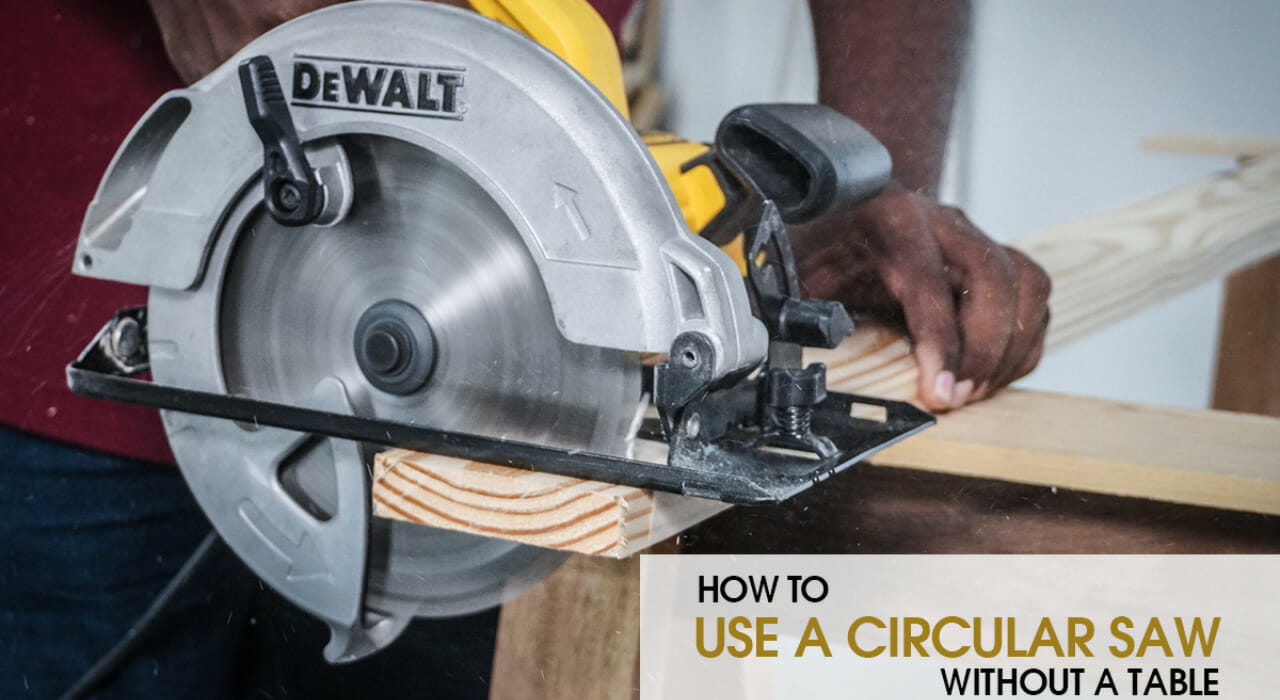

A circular saw is used to make straight cuts in wood, sheets, metals, and other materials. There is a high-speed blade in the circular saw to cut thick and bulky wood in the desired shape and designs. Circular saws are commonly used on the industrial level for big projects.

We have seen many woodworkers using circular saws with the table. But if you don’t have a table stop worrying about it. Let’s learn how to use circular saw without table saw? Yes, it is possible to cut the materials on the floor.

It is very important to purchase the right circular saw. Which is suitable for performing any hard task on the floor or anything else without a table. If you have not bought the right saw you will face errors while using it and the risk of injury will be high.

If you as a woodworker don’t know the use of a circular saw for your project. Come and experience something special with us. Hopefully, you will love to learn it.

There are mainly three methods to make a circular saw without a table.

How to use circular saw without table?-step by step

Sawhorses

Seahorses are the first method to operate a circular saw without the presence of a table. It is very easy to construct it.

- Choice of the material

You can use any material which is conveniently available to you. Plastic, wood, and metal are favorably used to construct a sawhorse you can choose any of them. Make surety that material should be cheap and easy to handle.

- Cutting off the sawhorse

It includes the cutting process of the top and legs of the sawhorse. A sawhorse has four legs cut in equal size approximately on the height of 32 to 36 inches. A rectangular-shaped sawhorse has on top what is called it’s head. Cut it in a standard size which is 2 to 4 feet. This process should be done very carefully with the help of a ruler to ensure accuracy.

- Attachment of head and legs

In this process attach all the departed legs and head with screws and nails. You can also add some braces but it is optional to enhance the stability of the sawhorse. The attachment of the whole structure should be at a 90-degree angle to the top.

- Paint the sawhorse

Now you have assembled all the parts the sawhorse is constructed now. To give it a professional look paint the sawhorse if you want. It will protect your sawhorse from termites and rust.

DIY Track

- Required materials

We need some materials to build DIY Track and these materials include, measuring tape, straight edge, clamps, circular saw, drill and drill bits, jigsaw, and plywood.

- Cut the base

Measure the base of the circular saw. Cut the chosen material according to it. The length should be from 4 to 8 feet.

- Attachment of guides and rails

The attachment of guides and rails makes a circular saw run it smoothly. It proves best for frictionless movement as it is attached between spaces with glue and screws while using the strips of wood and aluminum.

- Cut a groove

By using guide rails cut a shallow groove in the plywood with the help of your circular saw. The presence of a groove is important. It serves as a guide to a circular saw.

- Finish the track

Finish the construction track by protecting its edge with sand. It helps the circular saw to slide on a track properly.

- Test the track

Now the DIY track has been constructed. Make a test on the work surface to see whether it is fit for your circular saw or not. Observe the circular saw is running smoothly if not do some necessary adjustments.

Using insulation sheet

An insulation sheet is the best for the protection of the surface and avoiding noise pollution. Here are some steps in which you will learn how to use circular saw without table.

- Choose the length of the sheet

Choose the length of the sheet according to your project. The size of the circular saw decides the length of the sheet. The length of the sheet is more than the size of a circular saw. The sheet should be 1 inch thick as it provides stability.

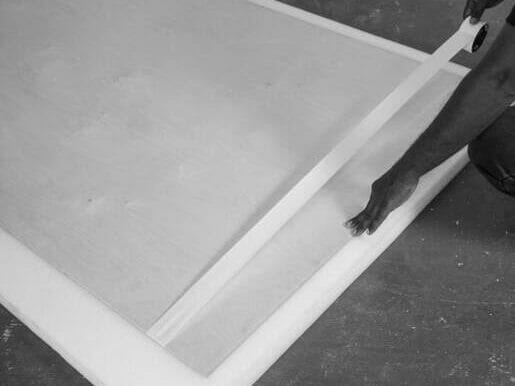

- Set up the sheet

Set the sheet flat on the surface properly. Make sure it does not happen during work. If it moved it will damage your project.

- Cut a hole

Make a hole in the insulation sheet with the help of a knife. Its diameter should be a little bit large than the size of the saw’s blade. The location of the hole should be in the center of the insulation sheet.

- Install the circular saw and make cuts

Set up your circular saw on the installation sheet in such a way that the hole of the sheet and the blade of the saw should be aligned. If it is set properly make some cuts to check its accuracy. Turn the saw carefully. Try some straight and angle cuts to ensure efficiency.

Can I use a circular saw on the wall?

Yes, of course, the use of a circular saw on the wall is the traditional way of working to make precise cuts. It is very necessary that the wall should be clean and flat. If the wall surface is appropriate surely use the circular saw on the wall.

Writer’s opinion

In all the above discussions, we have learned how to use circular saw without table. It is surely a practical method to use it on the floor with sheets and without sheets. Above mentioned three methods are applicable and widely experienced by woodworkers. While using the circular saw take some safety precautions to ensure your protection.