Cutting melamine with a circular saw can be a challenging task, as melamine is a type of hard plastic-coated particleboard that can easily chip or crack if not cut correctly. To achieve a clean and precise cut, it is essential to select the appropriate blade and set the saw blade depth correctly. Before making the cut, it is crucial to measure and mark the cutting line accurately and position the melamine sheet properly on a stable work surface. While cutting, apply light pressure and let the saw blade do the work, and wear protective gear such as eye protection and a dust mask. Lastly, after finishing the cut, it’s essential to sand the edges with sandpaper to smooth out any rough spots or burrs. Following these steps will help you cut melamine with a circular saw like a pro.

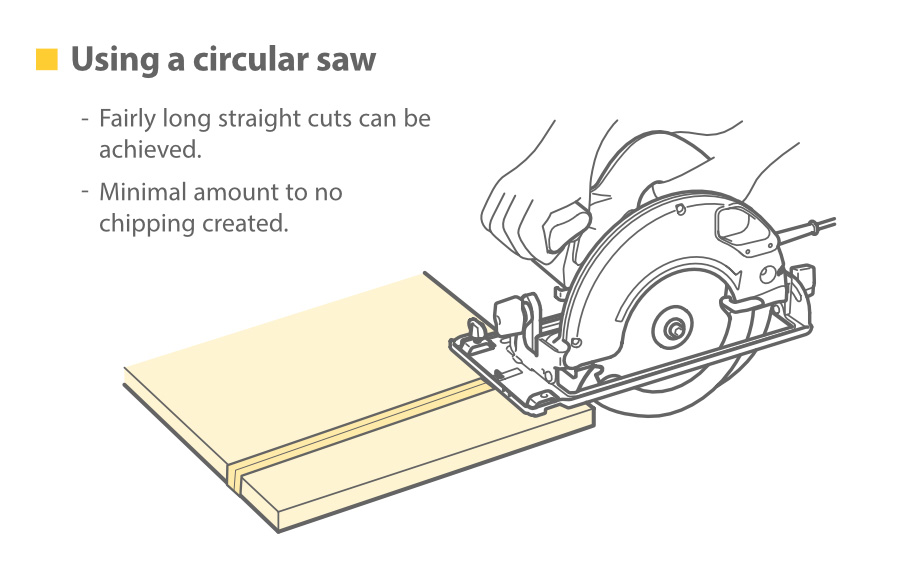

A DIYers guide to cutting MFC melamine-faced chipboard with no chipping Using Circular Saw

MFC, or melamine-faced chipboard, is a versatile and affordable material commonly used in DIY projects. However, cutting MFC can be tricky, as it has a tendency to chip and splinter easily. Here’s a guide to cutting MFC with no chipping:

- Choose the right blade: Use a fine-toothed saw blade with a high number of teeth, such as a 60-tooth or 80-tooth blade. This type of blade will produce a smoother cut with less chipping.

- Mark the cutting line: Measure and mark the cutting line on the MFC using a straight edge and a pencil. Ensure that the pencil line is on the waste side of the cut.

- Set the saw blade depth: Set the depth of the saw blade to slightly deeper than the thickness of the MFC. This will prevent the blade from cutting into the material below the MFC.

- Support the material: Place the MFC on a stable work surface, and support it with sawhorses or other supports to keep it flat and level while cutting. To prevent the bottom layer from splintering, place a piece of sacrificial wood or cardboard under the MFC.

- Cut the MFC: Turn on the saw and slowly guide it along the cutting line, keeping the blade on the waste side of the line. Apply light pressure and let the saw blade do the work. Be sure to wear eye protection and a dust mask while cutting MFC.

- Finish the cut: Once you reach the end of the cutting line, turn off the saw and carefully remove the MFC from the work surface. Sand the edges of the cut with sandpaper to smooth out any rough spots or burrs.

Is the cut edge going to be visible in the final installation?

Whether or not the final cut out edge of final cut MFC (melamine-faced chipboard) will be visible in the final installation depends on how the MFC is being final cut and cut depth used.

In some cases, such as when using MFC for shelving or cabinetry, the cut edges of removing material may be visible, especially if the edges of ply wood are left exposed. In these situations, it is essential to ensure that the cut edges when removing material are clean and smooth, with no chipping or splintering. Using a fine-toothed saw blade and supporting the material during cutting can help minimize chipping light sanding and ensure a clean, cut line.

Prevent the melamine from chipping

Preventing the melamine board from chipping is an essential step in achieving a clean and precise cut. Here are some tips to prevent chipping when cutting melamine:

- Choose the right blade: Use a fine-toothed saw blade with a high number of teeth, such as a 60-tooth or 80-tooth blade. This type of blade will produce a smoother cut with less chipping.

- Use masking tape: Place masking tape over the cutting line to help prevent chipping. This method can help to minimize the chipping on the surface of the melamine.

- Cut the melamine face down: When cutting melamine, it’s best to cut it face down. This means that the saw blade cuts through the melamine coating first, minimizing the chance of chipping on the visible side.

- Apply light pressure: Apply light pressure when cutting to allow the saw blade to do the work. Do not force the saw blade through the melamine, as this can cause chipping.

- Support the melamine: Support the melamine sheet during cutting to prevent it from vibrating or shifting, which can lead to chipping. Place the melamine sheet on a stable work surface, and support it with sawhorses or other supports to keep it flat and level while cutting.

Using a hand saw to cut melamine-faced board (MFC)

Using a hand saw to cut melamine-faced board (MFC) can be a bit trickier than using a power saw, but it’s still possible to achieve a clean and precise cut with a circular saw using the right tools and techniques. Here’s a step-by-step guide to cutting MFC with a hand saw:

- Choose the right saw: Use a fine-toothed saw with a high number of teeth, such as a tenon saw or a dovetail saw. This type of saw will produce a smoother cut with less chipping.

- Mark the cutting line: Measure and mark the cutting line on the MFC using a straight edge and a pencil. Ensure that the pencil line is on the waste side of the cut.

- Secure the MFC: Secure the MFC sheet to a stable work surface using clamps or a vice. This will prevent the material from moving or vibrating during cutting.

- Cut the MFC: Start by making a small pilot hole along the cutting line using a drill or a bradawl. This will provide a guide for the saw blade and help prevent chipping. Place the saw blade in the pilot hole and start cutting along the line. Apply light pressure and let the saw blade do the work. Be sure to keep the blade at a 90-degree angle to the MFC to ensure a straight cut.

- Finish the cut: Once you reach the end of the cutting line, carefully remove the saw blade from the MFC. Sand the edges of the cut with sandpaper to smooth out any rough spots or burrs.

Position the melamine chipboard properly for cutting methods

Properly positioning the melamine chipboard is essential for achieving a perfectly clean, and precise, cut line. Here are some steps to follow when positioning the chipboard for cutting:

- Choose a flat and stable work surface: Ensure that the work surface is flat and stable, such as a workbench or sawhorses. This will provide a solid foundation for the chipboard and prevent it from shifting or vibrating during cutting.

- Secure the chipboard: Use clamps or other appropriate tools to secure the chipboard to the work surface. This will prevent the chipboard from moving or shifting during cutting.

- Mark the cutting line: Use a straight edge and a pencil to mark the cutting line on the chipboard. Ensure that the line is straight and even.

- Allow for the blade width: When positioning the chipboard, take into account the width of the saw blade. Ensure that the blade will cut along the marked cutting line without damaging any surrounding material.

- Consider the direction of the cut: When cutting the chipboard, consider the direction of the cut. Ensure that the blade is cutting in the direction that is easiest and most comfortable for you. This will help you to maintain control of the saw and achieve a clean cut.

Use painters tape to protect the melamine board

Using painter’s tape to track and tear out forages and protect the melamine is an effective way to prevent chipping and damage if chips occur to the material during cutting. Here are some steps to follow when using painter’s tape to tear out track outages and protect top surface of the melamine:

- Apply painter’s tape to the cutting line: Before cutting, apply a strip of painter’s tape over the cutting line. Ensure that the tape is applied evenly and covers the entire cutting line.

- Score the tape with a knife: Use a sharp knife or razor blade to score along the cutting line through the painter’s tape. This will create a clean and precise edge for the saw blade to follow.

- Cut through the tape and melamine: Using the saw blade, cut through the painter’s tape and the melamine along the scored line. The painter’s tape will help to prevent chipping and damage to the melamine, resulting in a clean and precise cut.

- Remove the tape: Once the cutting is complete, carefully remove the painter’s tape from the melamine. This will reveal a clean and precise cut without any chipping or damage to the material.

What blades are recommended for cutting melamine-faced board (MFC)

When it comes to cutting melamine-faced board (MFC), using the right blade is crucial for achieving a clean and precise cut without chipping or splintering chip board. Here are two types of blades that are recommended for cutting MFC:

- Carbide-tipped saw blades: Carbide-tipped saw blades are ideal for cutting MFC. They have a sharper and more durable edge compared to standard saw blades, which helps to produce a clean cut with minimal chipping. Look for a blade with a high tooth count, such as 80 or 100 teeth, to achieve the best results.

- Hollow-ground planer blades: Hollow-ground planer blades are another option for cutting MFC. These blades are typically used in handheld power planers, but they can also be adapted for use in a table saw or circular saw. They have a sharp and precise edge that produces a clean and smooth cut, but they may require more frequent sharpening compared to carbide-tipped saw blades.

Choose the saw blade for cutting melamine

When it comes to cutting melamine, the saw blade you choose will greatly affect the quality of the cut. Here are a few factors to consider when selecting a saw blade for cutting melamine:

- Tooth count: The tooth count refers to the number of teeth on the saw blade. A higher tooth count will produce a smoother cut with less chipping. For cutting melamine, a saw blade with a tooth count of 80 to 100 is recommended.

- Blade quality: Choose a high-quality blade that is designed for cutting melamine. Carbide-tipped blades are a good option because they are more durable and have sharper teeth than regular saw blades. They are also less likely to chip the melamine during cutting.

- Blade diameter: The blade diameter should be appropriate for the saw you are using. A larger diameter blade will typically produce a smoother cut, but it may not fit in all saws. Ensure that the blade diameter is suitable for the saw you will be using.

- Blade type: Different saws require different types of blades. For example, a circular saw requires a circular saw blade, while a table saw requires a table saw blade. Ensure that you choose a blade that is compatible with your saw.

Cleaning up cut edges of melamine-faced board (MFC) using a router

Using a router to clean up the cut edges of melamine-faced board (MFC) is a great way to achieve a clean and smooth finish. Here are some steps to follow when using a router to clean up the cut edges of MFC:

- Choose the right bit: Select a router bit that is designed for cutting melamine, such as a carbide-tipped straight bit or a spiral up-cut bit. These bits will produce a clean and precise cut without chipping or tearing the melamine.

- Adjust the depth: Adjust the router’s depth so that the bit will remove just enough material to create a smooth edge without cutting too deep into the board. The depth should be slightly less than the thickness of the melamine to avoid cutting into the substrate.

- Secure the board: Clamp the board securely to a workbench or table to prevent it from moving during routing.

- Rout the edges: Slowly and carefully guide the router along the cut edge of the board. Keep the router moving in a smooth and continuous motion, and avoid stopping or starting in the middle of the cut.

- Sand the edges: After routing, use a fine-grit sandpaper to smooth out any rough spots or uneven areas along the edge of the board.

Is there a trick to cutting melamine without chipping?

there are several tricks to cutting melamine without chipping. Here are a few tips:

- Use a sharp blade: A dull blade will tear and chip the melamine, so it’s important to use a sharp blade. Consider using a carbide-tipped saw blade, as these are specifically designed for cutting melamine and will produce a cleaner cut.

- Use masking tape: Apply masking tape over the cut line to help prevent chipping. Make sure the tape is firmly adhered to the surface of the melamine and that the tape extends past the cut line.

- Cut from the back: Cutting from the back of the melamine can help prevent chipping, as the teeth of the saw blade will exit the board on the backside, leaving a cleaner cut on the front.

- Take it slow: Cutting too quickly can cause the melamine to chip. Take your time and make slow, steady cuts, letting the saw blade do the work.

- Score the cut line: Use a sharp utility knife to score the cut line before making the cut. This will help guide the saw blade and prevent chipping.

Which saw should you use to cut melamine chipboard without chipping?

When cutting melamine chipboard without chipping, it’s recommended to use a saw blade with fine teeth and a low tooth count. A circular saw or a table saw with a blade designed for cutting melamine is ideal. Look for saw blades that are designed specifically for cutting melamine, as these will have a special coating that helps reduce chipping. Another option is to use a jigsaw or a handsaw with a fine-toothed blade, but these may require more skill and patience to achieve a clean cut without chipping

Protective gloves

Protective gloves are a type of personal protective equipment (PPE) that are designed to protect your hands from potential hazards in the workplace or during certain activities. They are made from a variety of materials, including latex, nitrile, vinyl, neoprene, and leather, depending on the type audience engagement and site of protection required.

In the context of cutting melamine, protective gloves can help protect your hands from cuts, scrapes, and potential exposure to harmful chemicals if you are using certain types of adhesives or solvents. However, it’s important to choose the right type of glove for the task at hand depending on your settings. For example, if you are working with solvents, you should use chemical-resistant gloves, while cut-resistant gloves may be more appropriate when using power tools.

Safety and PPE (Personal Protection Equipment)

Safety and PPE (Personal Protective Equipment) are crucial components of any workplace or activity where there is a risk of injury or exposure to hazards. PPE includes equipment such as hard hats, safety glasses, gloves, earplugs, respirators, and protective clothing, all of which are designed to protect workers from injury, illness, or exposure to harmful substances.

Can you use a circular saw to cut melamine?

You can use a jigsaw or circular saw to cut melamine. However, it’s important to use the right blade and take some precautions to prevent chipping. As melamine is a brittle material, it is prone to chipping when cut with power saws or blades that are not designed for this material. It is recommended to use a blade with fine teeth and a low tooth count, designed specifically for cutting melamine.

How do you cut melamine with a circular saw without chipping?

To cut melamine with a circular saw without chipping, you can follow these steps:

- Measure and mark the melamine where you want to make the cut.

- Apply masking tape along the line you marked to help prevent chipping.

- Score the line with a sharp utility knife or scoring tool to create a groove for the saw blade to follow.

- Adjust the depth of the saw blade so it’s just slightly deeper than the thickness of the melamine.

- Use a fine-toothed blade with a high tooth count, specifically designed for cutting melamine. The blade should have a negative hook angle to reduce the risk of chipping.

- Cut the melamine slowly and steadily, keeping the blade aligned with the scored line and using a guide if necessary.

- Make sure the blade is sharp and in good condition before cutting, as a dull or damaged blade can cause chipping.

What circular saw blade is best for melamine?

The best circular saw blade for cutting melamine is a blade specifically designed for this type of material. Melamine is a brittle material that can chip easily when cut with the wrong hand held circular saw blade, so it’s important to choose a blade with a high tooth count and a negative hook angle. A negative hook angle means that the teeth of the blade are angled away from the direction of rotation, which helps to reduce the risk of chipping.

When selecting a circular saw blade for cutting melamine, look for a blade with a high tooth count of at least 80 or more, and a diameter that is appropriate for your saw. The blade should also have a thin kerf, which will reduce the amount of material that is removed during the cut, and help to prevent tear out minimize chipping.

What is a good blade for cutting melamine?

A good blade for cutting melamine is one that is specifically designed for this material, with a high tooth count and a negative hook angle. Here are some examples of blades that work well for cutting melamine:

- Freud LU97R010 10-Inch 80 Tooth TCG Saw Blade: This blade has a triple-chip grind tooth design and a negative hook angle, which helps to prevent chipping and provides a smooth, clean cut.

- CMT 214.080.10 Industrial Thin Kerf Saw Blade: This blade has 80 teeth with a negative hook angle, and a thin kerf design that reduces material waste and improves cutting accuracy.

- DeWalt DW7296PT Precision Trim 12-Inch 96 Tooth ATB Crosscutting Saw Blade: This blade has 96 teeth and an alternate top bevel (ATB) tooth design that produces clean, precise cuts in melamine and other laminates.

- Forrest Woodworker II 10-Inch 80 Tooth ATB Saw Blade: This blade features a high tooth count and an ATB tooth design, making it ideal for cutting melamine without chipping.

FAQS

- Can I cut melamine with a circular saw? Yes, you can cut melamine with a circular saw. However, it is important to use the right blade and cutting techniques to prevent chipping and splintering.

- What kind of blade should I use to cut melamine? You should use a blade with a high tooth count (80 or more) and a negative hook angle to cut melamine. This type of blade will produce smooth, clean cuts without chipping or splintering.

- How do I prevent chipping when cutting melamine? To prevent chipping when cutting melamine, use a sharp blade with the correct tooth count and hook angle. Additionally, you can apply masking tape to the cut line to help protect the surface of the melamine during cutting.

- Can I use a table saw to cut melamine? Yes, you can use a table saw to cut melamine. Just like with a circular saw, it’s important to use the right blade and cutting techniques to prevent chipping and splintering.

- How do I clean up the edges of melamine after cutting? You can use a router or a sanding block to clean up the edges of melamine after cutting. Make sure to wear appropriate protective gear and take your time to avoid damaging the material.

- What other safety precautions should I take when cutting melamine? When cutting melamine, always wear appropriate personal protective equipment (PPE), including eye protection, ear protection, and gloves. Additionally, be sure to use the correct blade and cutting techniques to minimize the risk of injury or damage to the material.

Conculusion

Cutting melamine requires the right tools and techniques to avoid chipping, splintering, or other damage to the material. Circular saws and table saws can be used for cutting melamine, but it’s important to use the right blade with a high tooth count and negative hook angle. Additionally, applying masking tape to the cut line can help protect the surface of the melamine during cutting. After cutting, you can clean up the edges with a router or sanding block, and always take appropriate safety precautions such as wearing PPE. With the right tools and techniques, you can achieve smooth, clean cuts on melamine without chipping or splintering.