A scroll saw is a popular tool among woodworkers that allows them to make intricate and detailed cuts in thin wood. However, to achieve precise cuts, it’s important to choose the right blade. In this review, we’ve compiled a list of the 7 best scroll saw blades for precise cuts in 2023.

- Flying Dutchman Ultra Reverse blades – Known for their durability and ability to cut through a variety of materials.

- Olson Scroll Saw Blades – Popular for their precision and clean cuts.

- Pegas Modified Geometry blades – Ideal for those who want to make intricate and precise cuts.

- Bosch Scroll Saw Blades – A budget-friendly option that still delivers good performance.

- Delta Power Tools Scroll Saw Blades – Known for their long-lasting durability.

- SE PS2915 Jeweler’s Saw Blades – Perfect for intricate jewelry-making work.

- Dewalt Scroll Saw Blades – Known for their durability and ability to cut through thick materials

Best scroll saw blades for hardwood

When it comes to cutting hardwoods with a scroll saw, it’s important to choose a blade that is strong, durable, and able to maintain its sharpness over time. Here are some of the best scroll saw blades for cutting hardwoods:

- Olson Saw PG49802 Precision Ground Scroll Saw Blade – This blade is made from high carbon steel and features precision ground teeth that allow for smooth and accurate cuts in hardwoods. It’s also very durable and long-lasting, making it a great investment for anyone who works with hardwoods frequently.

- Flying Dutchman Spiral – This blade is known for its ability to make precise cuts in dense materials like hardwoods. It features a spiral design that helps to reduce friction and heat buildup, which can help to prolong the life of the blade.

- Olson Saw FR49501 – This blade has a wide kerf and large gullets, which make it ideal for cutting thicker hardwoods. It’s also very durable and long-lasting, which makes it a great choice for anyone who does a lot of woodworking.

- Pégas Super Skip Tooth – This blade has a unique tooth design that helps to reduce the amount of dust and debris that is produced during cutting. It’s also very strong and able to handle the rigors of cutting through dense hardwoods.

- Bosch SS5-15 – This blade is made from high carbon steel and features precision ground teeth that allow for smooth and accurate cuts in hardwoods. It’s also very durable and long-lasting, making it a great choice for anyone who works with hardwoods frequently.

Which wood type does a scroll saw blade cut the best?

Scroll saw blades can be used to cut a variety of wood types, including softwoods like pine and cedar, hardwoods like oak and cherry, and even engineered wood products like MDF and plywood. However, the type of wood that a scroll saw blade cuts best can depend on several factors, including the blade size and type, tooth count, and thickness.

For example, a skip-tooth blade with a lower TPI (teeth per inch) count may be better suited for cutting thicker, denser hardwoods, while a reverse-tooth blade with a higher TPI count may be better suited for cutting thinner, softer woods. Additionally, some blade types like spiral blades and precision-ground blades may offer greater maneuverability and control when cutting intricate designs in a variety of wood types.

Flying Dutchman Spiral – Best Scroll Saw Blade For Beginner’s

The Flying Dutchman Spiral blade is a great scroll saw blade for beginners. This blade is known for its ease of use and versatility, making it an excellent choice for those who are just starting out with their scroll saw. It has a spiral tooth pattern that allows for smooth and precise cuts on a variety of materials, including wood, plastic, and metal. The blade is also designed with a reverse tooth configuration, which helps prevent splinters and provides a cleaner finish. Additionally, the Flying Dutchman Spiral scroll see blade is made from high-quality materials, which means it is durable and long-lasting. Overall, if you’re a beginner looking for a reliable and easy-to-use scroll saw blade, the Flying Dutchman Spiral blade is definitely worth considering.

Olson Saw PG49802 Precision Ground Scroll Saw Blade – Best for Hardwood

The Olson Saw PG49802 Precision Ground Scroll Saw Blade is an excellent choice for cutting hardwoods. This blade is known for its precision and clean cuts, making it ideal for intricate woodworking projects. The blade is made from high-quality carbon steel and is precision-ground for exceptional sharpness and durability. The tooth geometry is designed to prevent burning and minimize splintering, which is essential when working with hardwoods.

Olson Saw SP46500

The Olson Saw SP46500 is a popular scroll saw blade known for its versatility and precision. It is a skip-tooth blade, meaning most common for skip tooth blades’ third tooth in configuration is the crown tooth blade and every other two tooth blade is missing, which allows for easy chip removal and prevents overheating of the blade. This makes it an ideal choice for cutting a variety of materials, including wood, plastic, and soft metals. The blade is made from high-carbon steel and is heat-treated to ensure maximum durability and longevity

Using Blades

Using the right blade is essential to achieving the best results with a scroll saw. Here are some tips for using the best scroll saw blades for hardwood:

Choose the right blade for your project: Different blades are designed for different materials and purposes. Make sure to choose a blade that is appropriate for the material you are cutting and the level of precision you require.

Install the scroll, the pinned scroll, blades, and blade properly: Ensure that the blade is properly installed and tightened before using the scroll, pinned blades, or saw. Follow the manufacturer’s instructions carefully to avoid any accidents or damage to the blade, the pinned scroll, pinned blades, or saw.

Start with the blade set a slow speed: It’s a good idea to start with the blade set a slow speed when beginning a cut. Gradually increase the blade set and speed of stack cutting as you become more comfortable with the blade set and the material you are cutting.

Use dull blades and light pressure: Avoid applying too much pressure to dense wood with the blade as this can cause it to bend or break. Let the blade do the work and guide it through the material with gentle, steady pressure.

Use a blade lubricant: Using a blade lubricant can help extend the life of the blade and improve the quality of the cut. Apply the lubricant directly to the blade before starting the cut.

Keep the blade clean: Clean the blade regularly to remove any debris or buildup that can affect its performance. Use a brush to remove any sawdust or debris from the teeth of the blade.

How Many Cuts Can You Make with a Scroll Saw Blade?

The number of cuts you can make with a scroll saw blade depends on several factors, including the type of blade, the material you are cutting, and the level of precision required. Generally, a scroll saw blade can last anywhere from a few cuts to several hours of continuous use before it needs to be replaced.

The life of the blade reviews a scroll blades or saw blade can also be affected by the user’s technique, the speed of the saw, and the amount of pressure applied to the scroll blades blade. If a scroll blades blade is pushed too hard or bent, it may break or become a dull blades more quickly.

Size and Thickness

Scroll saw cross pin and blades come in different sizes and thicknesses, and selecting the accurate cross pin andless scroll saw blades and the accurate scroll see blade industry the right size and thickness is important to achieve the best results with premium blades on your scroll saw.

The blade size of of a scroll saw blade refers to its length and is typically measured in inches or millimeters. The most common blade sizes range from 2.5 inches to 7 inches in length. Smaller blades are suitable for more, intricate shapes and detailed cuts, while larger blades are better for cutting thicker materials and straight lines.

The thickness of standard blades on a scroll saw blade refers to the width of the blade and is typically measured in numbers that range from 12 to 28. The higher the number, the larger blades thinner the blade. Thinner standard blades are suitable for more intricate shapes and detailed cuts, while thicker blades are better for cutting thicker materials and straight lines.

2 Material (Thickness, density)

The thickness and density of the material being cut are important factors to consider when selecting a scroll saw blade.

Thicker materials require a thicker blade, with a larger thickness, as the blade needs to be strong enough to handle the resistance of the material. Thinner blades may break or bend when cutting thicker materials, which can result in inaccurate cuts or damage to the blade. On the other hand, thinner materials require a thinner blade with a smaller thickness to achieve the level of precision required.

The density of the material being cut is also important, as denser materials require a thicker blade, with more teeth per inch (TPI) to achieve a clean and accurate cut. Materials such as hardwoods, metals alloy steel, and thick plastics require a thinner, smaller blade with a higher TPI, while softer materials such as balsa wood or foam require a smaller blade, with a lower TPI.

3 Precision and maneuverability

Precision and maneuverability are important factors to consider when selecting a scroll saw blade.

Blades with a higher TPI (teeth per inch) are better for achieving a high level of precision in intricate and detailed cuts, while other blades, with smaller blades and a lower TPI are better for making smoother, straighter cuts in thicker materials.

Blades with a spiral design, such premium blades such as spiral blades or reverse-tooth blades, are more maneuverable and can easily make intricate cuts with tight turns and curves. These premium blades can also make plunge cuts, which allows the user to start a smooth cut in the middle sharper cutting straight lines to edge of smooth cut in a piece of material.

Blades with a flat or skip-tooth design are better for cutting thicker materials and making straighter, smoother cuts. These blades have fewer teeth per inch than other blades, which allows them to remove material more quickly and efficiently sharper cutting edge through.

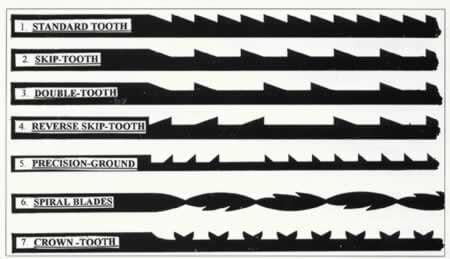

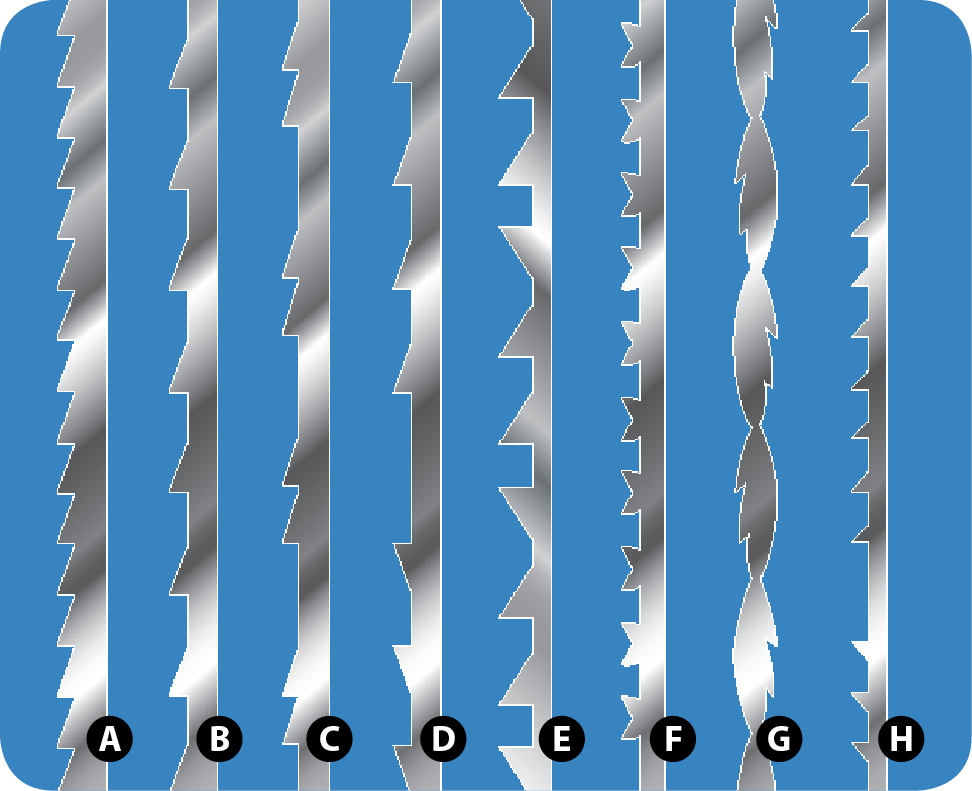

Blade Type

There are several types of various compatible scroll saws, and blades available, each designed for specific cutting tasks. Some common types of compatible scroll saws and blades include:

- Standard tooth blades – These blades have evenly spaced teeth and are suitable for making smooth cuts in thin to medium-thick materials.

- Skip tooth blades – These blades have teeth that are spaced further apart than standard tooth blades, which makes them ideal for cutting thicker materials and making faster, rougher cuts.

- Double tooth blades – These blades have two teeth side-by-side, which makes them suitable for cutting thick and dense materials.

- Spiral blades – These blades have a spiral shape that allows for more maneuverability and is ideal for making intricate cuts and tight turns.

- Reverse tooth blades – These blades have teeth that point downwards, which helps to prevent splintering on the top of the material being cut. They are suitable for cutting fragile materials like veneers and laminates.

- Crown tooth blades – These blades have teeth that are shaped like a crown, which helps to prevent the blade from drifting during the cut. They are ideal for making precise cuts in thicker materials.

Olson Saw FR49501– Perfect Scroll Saw Blade For Thick Wood

The Olson Saw FR49501 is an excellent choice for cutting thick, soft wood with a scroll saw. This blade has a skip-tooth design, which means that every other tooth in the blade industry you stack cutting through is missing, allowing for more efficient chip removal and faster cutting in thicker materials soft wood.

With a thickness of 0.057 inches dense wood and 15 teeth per inch thin dense wood used, this blade can handle wood up to 2 inches thick with ease. The blade is made from high-carbon steel and is heat-treated for durability and long life.

The skip-tooth design of the blade reviews the Olson Saw FR49501 also helps to prevent the blade from overheating during use, which can cause the blade to warp or break. The blade’s ” skip tooth blade” design also reduces the chance of the wood getting caught or pinched by skip tooth blade, which can cause the blade to break or cause inaccurate cuts.

5 Types of Scroll Saw Blades

There are several types of scroll saw blades available, each designed for specific cutting tasks. Here are five common types of scroll saw blades:

- Standard Tooth Blades – These blades have evenly spaced teeth and are suitable for making smooth cuts in thin to medium-thick materials.

- Spiral Blades – These blades have a spiral shape that allows for more maneuverability and is ideal for making intricate cuts and tight turns.

- Reverse Tooth Blades – These blades have teeth that point downwards, which helps to prevent splintering on the top of the material being cut. They are suitable for cutting fragile materials like veneers and laminates.

- Double Tooth Blades – These blades have two teeth side-by-side, which makes them suitable for cutting thick and dense materials.

- Skip Tooth Blades – These blades have teeth that are spaced further apart than standard tooth blades, which makes them ideal for cutting thicker materials and making faster, rougher cuts.

7 Crown-tooth blades

Crown-tooth spiral scroll saw blades, blades, are a type of spiral scroll saw blades with blade that have teeth shaped like a a crown like shape. This crown like shape design helps to prevent the blade from drifting during the cut, making it ideal for making precise cuts in thicker materials. Here are seven examples of crown-tooth spiral scroll saw blades:

- Olson Saw CR49000 – This crown-tooth blade is made from high-carbon steel and has 12 teeth per inch. It is suitable for cutting wood, plastic, and soft metals.

- Pegas Swiss Made Pinned Crown Tooth Scroll Saw Blades – These crown-tooth blades are made in Switzerland and have a unique tooth design that allows for more precise cuts in thick materials.

- Flying Dutchman Crown Tooth Scroll Saw Blades – These blades have a double-tooth pattern that helps to prevent chipping and breaking during use. They are suitable for cutting wood, plastic, and other materials.

- Bosch ST140CFP Crown Tooth Scroll Saw Blades – These blades are made from high-carbon steel and have a precision-ground tooth design that allows for more accurate cuts in thicker materials.

- SECO Crown Tooth Scroll Saw Blades – These blades are made from hardened and tempered steel and have a unique crown-tooth design that helps to prevent the blade from drifting during the cut.

- Delta Power Equipment Corporation Crown Tooth Scroll Saw Blades – These blades have a high-carbon steel construction and a crown-tooth design that helps to prevent the blade from wandering during the cut.

- Mikisyo Power Grip Crown Tooth Scroll Saw Blades – These blades are made in Japan and have a unique tooth design that allows for more efficient chip removal and faster cutting in thicker materials.

Crown-tooth blades are an excellent choice for anyone looking to make precise cuts in thicker materials with a scroll saw. The unique crown tooth blade design of these blades helps to prevent drifting, sharper cutting edge and ensures accuracy and precision during the cut.

Skip tooth blades

Skip tooth blades are a type of scroll saw blade that have every other tooth removed, creating wider gaps between teeth. This design allows for faster, more aggressive cutting and is well-suited for thicker materials, such as hardwoods and some metals. Skip tooth scroll blades can also be useful for roughing out shapes or cutting straight lines, but may not be the best choice for intricate designs or tight curves, as the wider gaps between teeth can cause more tear-out and splintering.

Advantages of Scroll Saw Blades

There are several advantages to using most scroll saws and blades, including:

- Versatility – Scroll saw blades can be used to cut a variety of materials, including wood, plastic, metal, and more.

- Precision – Scroll saw blades allow for very precise cuts, making them ideal for intricate and detailed work.

- Maneuverability – Scroll saws are designed to make tight turns and intricate cuts, which allows for greater maneuverability than other types of saws.

- Smooth Cuts – Scroll saw blades produce very smooth cuts, which reduces the need for sanding and finishing work.

- Low Noise and Vibration – Scroll saws produce minimal noise and vibration, making them ideal for use in shared spaces or for extended periods of time.

- Minimal Material Waste – The narrow kerf of scroll saw blades means that there is less material waste compared to other types of saws.

- Easy Blade Changes – Most scroll saws have a quick-release mechanism for changing blades, which makes it easy to switch between blade types or replace a worn-out blade.

Do I need pin-end blades or pin-less blades?

The choice between pin-end blades and pin-less blades depends on your specific scroll saw and the type of work you plan to do.

Pin-end blades have pins at the end of the blade that fit into slots in the scroll saw’s blade holders. These pins keep the blade securely in place during use and prevent it from twisting or popping out of the holder. Pin-end blades are typically easier to install and remove than pin-less blades, making them a good choice for beginners or anyone who wants to change blades frequently.

Pinless blades and-less blades, on the other hand, do not have pins and are clamped directly into the blade holders on the scroll saw. This allows for more flexibility in the types of the pinless precision ground blades and plain end blades have that can be used and greater control over the tension of the blade. Pinless blades and-less blades are typically thinner and more flexible than pin and precision ground tooth and-end blades, which makes them a good choice for making intricate and detailed cuts.

1.1 Ground hardened steel blades

Ground hardened alloy steel, blades are a type of scroll saw blade that are made from premium grade steel high-carbon, alloy steel, that the premium grade steel has been heat-treated and ground to a fine edge. These various alloy steel blades are known for their durability and ability to hold an edge for a long time, making them a good choice for cutting hard materials like metal or dense hardwoods.

The process of hardening and tempering the steel used in these blades involves heating it to a high temperature and then rapidly cooling it to create a very hard, durable material. The hardened steel blade is then ground to a precise edge that can cut through even the toughest materials with ease.

Ground hardened steel blades come in a variety of shapes and sizes, including flat-end milled blades, a spiral blade, and skip-tooth milled blades. They are typically more expensive than other types of scroll saw blades, but their durability and long life make them a good investment for anyone who plans to do a lot of heavy-duty cutting.

Teeth Per Inch (TPI)

Teeth per inch (TPI) is a measurement of the number of teeth on a scroll saw blade within an inch of its length. It is an important factor to consider when selecting a scroll saw blade because it determines the blade’s ability to make smooth and precise cuts in different materials.

Blades with a high TPI have more teeth per inch and are better suited for cutting thin materials like paper, veneer, and plastics. They produce smoother cuts with less tear-out and require less sanding or finishing work after cutting. Blades with a low TPI, on the other hand, have fewer teeth per inch and are better suited for cutting thicker materials like wood or metal. They can remove material faster and are better at cutting through dense materials, but they may produce rougher cuts that require more finishing work.

FAQS

What is a scroll saw blade?

A scroll saw blade is a thin, narrow blade that is used in a scroll saw machine to cut intricate curves and shapes in a variety of materials, including wood, metal, and plastic.

How do I choose the right scroll saw blade for my project?

The right scroll saw blade for your project will depend on several factors, including the type of material you’re cutting, the thickness of the material, and the complexity of the design. Generally, blades with higher TPI counts are better suited for cutting thinner materials, while other blades, with lower TPI counts are better for cutting thicker materials.

What is the difference between pin-end and pinless scroll saw blades?

Pin-end blades have small pins on each end that fit into the scroll saw machine’s blade holders, while pinless blades are clamped into the blade holders. Pinless blades are more versatile and allow for slower speeds and more intricate cuts, but pin-end blades are easier to install and can be a better choice for beginners.

How long do scroll saw blades last?

The lifespan of a scroll saw blade can vary depending on several factors, including the type of blade, the material being cut, and the user’s technique. Generally, a high-quality blade should last for several hours of cutting time, but it’s important to monitor the blade’s performance and replace it as needed to ensure accurate and safe cuts.

Can scroll saw blades be sharpened?

Yes, some scroll saw blades can be sharpened using a specialized sharpening tool or file. However, not all blades are designed to be sharpened, and improper sharpening can damage the blade and affect its performance.

How do I change a scroll saw blade?

To change a scroll saw blade, first, unplug the machine and loosen the blade tension. Remove the blade from the blade holders, and then insert the new blade, making sure that it is in tight corners oriented correctly. Tighten the blade tension and test the machine to ensure that the blade is in tight corners installed correctly and functioning properly.

Can I use a scroll saw blade to cut metal or plastic?

Yes, some scroll saw blades are designed for cutting metal and plastic materials. However, it’s important to choose the right type of blade for the specific material being cut and to use caution and protective equipment when cutting these materials.

Conculusion

Scroll saw blades are an essential tool for cutting intricate curves and shapes in a variety of materials, including wood, metal, and plastic. When choosing a scroll saw blade, it’s important to consider factors such as the type of material being cut, the thickness and density of the material, the complexity of the design, and the user’s experience level. Pinless plain end blades are more versatile and allow for more intricate cuts, while pin-end plain end blades are easier to install and can be a better choice for beginners. Additionally, the TPI count, blade type, and material composition can all affect the blade’s performance and lifespan. With the right blade and technique, a scroll saw can be a powerful tool for creating precise and detailed cuts in a wide ran7 Best Scroll Saw Blades for Precise Cuts Review 2023